- Animation, Film, Movies, Movie Trailers, T.V. Filming (Directors, Producers, Cinematographers)

- Music, Entertainment, Music Awards

- Animals, Insects, Pets, Animal Lovers

- Sports, Football, Basketball, Baseball, Hockey, Soccer, Swimming, Fishing, Volleyball, Golf

- Travel, Beaches, States, Cities , Hotels, Events, New Year's Celebration World

- Gaming, Birthdays, holidays, Magic Tricks, Entertainment, Pranks, Optical Illusions

- Blogs, Commercials, Inventions, People, Workers, Working Tools, Strange, Super Natural, World Records

- Comedy, Jokes, Comedians, Pranks

- Entertainment, Hollywood, Show Biz, Celebs, Academy Awards (Oscars, Golden Globe Awards), Fashion, Pictures (Photos, Poses), Dances, Statues, Sculptor, Body Art

- Crimes, Civil, Criminal, Torts, Traffic, Supreme Court (laws), Jail, Prison, Good Samaritans

- How-to, Education, History, Installation, Repairs, Math, Medical, Dentistry, Motivation, Speeches, Thoughts (Views)

- Vehicles (Cars, Motorcycles, Trucks, Buses),Trains, Hacks, Painting, Washing, Detailing

- Airplanes, Helicopters, Military, Guns, War, Nuclear Reactors, Nuclear Weapons, Skydiving( wing suits, Base Jumping)

- Boats, Ships, Yachts, Sailing Ships, Cargo Ships, Submersible Submarines, Jet Ski

- Ads, Business, Crypto, Marketing, Online Business, Real Estate, Stocks, Federal Reserve/Money, Business (Tycoons, Experts)

- Fitness, Weight Lifting, Health, Healthy Foods, Foods, Fish, Crab, Seafoods

- Oceans, Seas, Rivers, Lakes, Streams, Storms, Rain, Snow, Volcanos

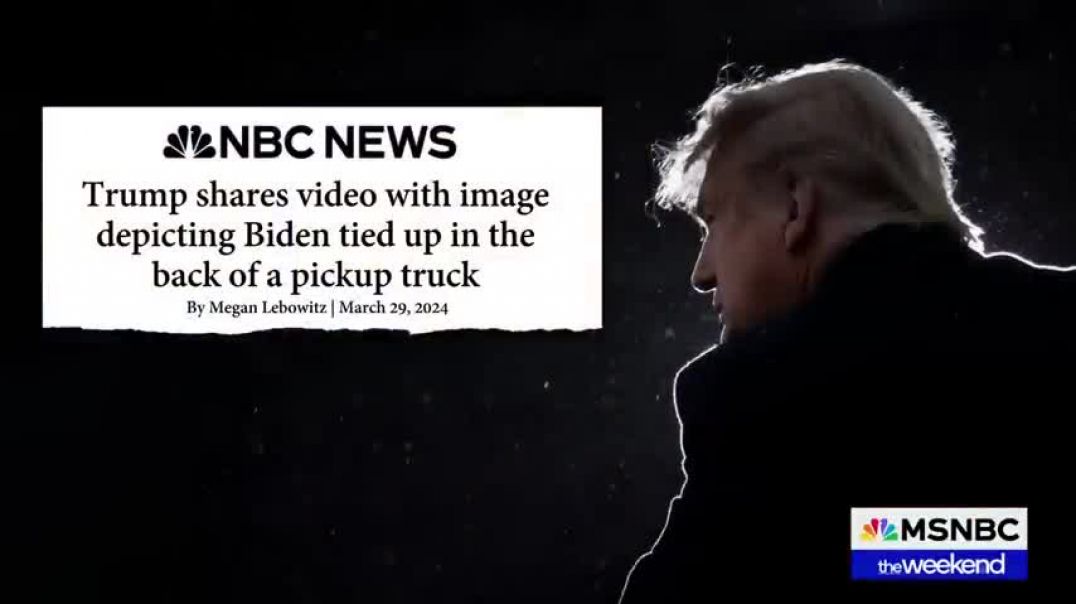

- Breaking News, News, Politics, Presidents, First Ladies, Earthquakes, Fires

- other

- Love, (Flirting, Crush), Relationships, Friendships, Romance, Relationship Breakups, Single, Lonely, Divorce

Understanding the Tesla Model S Performance Motor

Join me for a deep dive into the details of the 18,000 RPM performance rear motor and drive unit from a 2015-2016 Tesla Model S P90D. This drive unit is similar to the one used in the 2017-2020 P100D. The video is divided into four sections showing: 1. The motor and gears. 2. The high-performance bearings. 3. The lubrication system. and 4. The cooling system.CORRECTIONS: Thank you to everyone for catching my errors. There are always errors ;)1. The Nissan Leaf ring gear is held on with 8 bolts, not 6.2. The fluid in this drive unit is Dexron 6 transmission fluid.3. Induction motor rotors do not have poles, just the stator. The 60 slot stator has four poles.4. Silicon Nitride is a ceramic material.TIMELINE:0:00 Start0:10 Introduction1:35 Gearbox housing2:10 Video Section 1 - Gears and Motor Rotor2:45 The giant differential ring gear with 16-bolts!4:20 The giant differential case bearings4:50 The differential case speed at 250 km/h (155 mph) = 1841 RPM5:15 MUST SEE Comparing the Tesla 213mm x 50mm. ring gear with 78 teeth (Factors 2, 3, 13) to a Chevrolet Bolt EV and Nissan Leaf EV5:40 A Chevrolet Bolt EV differential 198mm x 34.3mm ring gear with 12-bolts.6:10 A Nissan Leaf EV differential 200mm x 32mm ring gear with 8-bolts!7:30 The Counter Shaft (Jack Shaft) with 25 (Factors 5, 5) pinion gear teeth. 78/25 = 3.12:1 Gear ratio from countershaft to the differential case8:50 The countershaft speed at 250 km/h (155 mph) = 5743 RPM9:30 The motor shaft with 25 teeth drives 78 teeth on the countershaft for another gear reduction of 78/25 = 3.12:110:08 The motor shaft speed at 250 km/h (155 mph) = 17,919 RPM11:20 See all three gears in the reduction gearbox with an overall gear reduction of (78/25) x (78/25) = 9.7344:112:05 MUST SEE The AC Induction Motor Rotor with 74 bars13:25 Motor specifications for power, torque, and gear ratio15:00 MUST SEE Ceramic Bearings (Silicon Nitride) on the rotor from the SKF Group (skf.com)16:22 MUST SEE Close up view of silicon nitride bearing18:20 The motor rotor speed sensor reluctor wheel (tone ring)19:22 Must SEE The rotor installed on the drive gear and the functioning gearbox20:18 Video Section 2 - Specialized Bearings21:21 The 60 slot four-pole stator and housing23:05 The oil pump and how it is overdriven by the differential ring gear 23/78 = 0.2948:1 gear ratio (3.339 times faster than the ring gear)23:55 MUST SEE The function of the oil pump (it may surprise you)26:27 Motor shaft (Input Shaft) bearing reference speed and limiting speeds 27:30 How to run bearings at higher speeds than their limiting speeds29:54 Video Section 3 - Lubrication30:25 Drain and fill plug locations30:50 Gearbox vent and inverter vents31:05 Sport model label31:39 MUST SEE Four different sealed areas in the drive unit32:46 Video Section 4 - Cooling System33:30 MUST SEE The coolant inlet port and the two paths coolant takes33:53 Up for rotor cooling and gearbox cooling35:03 Down for stator and inverter cooling36:05 Coolant from the rotor moves to the gearbox heat exchanger and the outlet port37:25 Stator temperature sensors38:10 Coolant from the stator to the inverter coolant passages38:28 Stator coolant temperature sensor38:35 MUST SEE Insulated-Gate Bi-Polar Transistor (IGBT) module coolant passages and flow through gearbox passages40:34 Inverter coolant outlet temperature sensor40:45 The gearbox oil-to-coolant heat exchanger41:38 Coolant outlet port to coolant pump and onboard charger module under the back seat.41:55 Drive unit cooling system summary43:04 IGBT inverter modules installed and inverter cover43:40 High voltage battery cable connections and low voltage connections at the inverter44:35 Video summaryABOUT USWeber State University (WSU) Davis Campus - Automotive Technology Department - Advanced Vehicles Lab. A technical description and demonstration of the Tesla P90D Rear Drive Unit (RDU). We teach current vehicle technologies to our automotive students at Weber State University and online. For more information visit: http://www.weber.edu/automotiveThis video was created and edited by Professor John D. Kelly at WSU. For a full biography, see http://www.weber.edu/automotive/J_Kelly.htmlVisit my other youtube channel https://www.youtube.com/user/vibratesoftware to see the amazing NVH app for vibration diagnosis! ADDITIONAL TRAINING FOR YOUJoin us for hybrid and electric vehicle training with two online courses and in a 5-day on-campus boot camp with Professor John D. Kelly. See http://www.weber.edu/evtraining DONATE TO OUR DEPARTMENTPlease consider a donation to the Department of Automotive Technology at Weber State University here: http://advancement.weber.edu/Automotive

miytube

![City Car Driving - Tesla Model Y [Steering wheel gameplay]](https://miytube.com/upload/photos/2024/03/0faa3dab4a7765ba9f91b4f35d497ddb6f07d294QUxGtXWkVwtACIEb6jHD.video_thumb_8745_11.jpeg)